Following on from last weeks success with the cyclone separtor, I was eager to get the unit attached to the shot blast cabinet. The model I have (an old model Sealey SB972) does not have a connection for a dust extraction hose. However, it does have two air inlets, one of which has an air filter. My first idea was to utilise one of these inlets as the connection for the dust extraction. The problem, I quickly found through testing, was that the suction was greater than the air being drawn through the one remaining inlet and this would doublessly cause an implosion to the weakest part of the rig. I figured that I had two options; either reduce the power of the vacuum or increase airflow through the cabinet. However, with regards to that latter; I really didn't want to have to cut more holes into cabinet if I didn't have to.

With this in mind, I then had a brainwave - remove the ineffective light unit (I will be upgrading to internal LED light strips anyway) and utilise the remaining aperture as the basis for creating a custom extraction port. Crucially this would leave the two existing air inlets as they were and keep airflow maximised;

With the light fitting out, I had a sizable hole to work with;

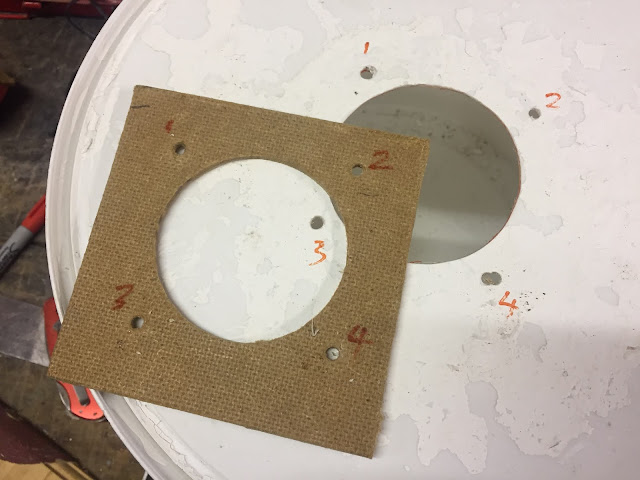

I set to work by cutting out a blanking plate from 2mm mild steel sheet, using the old light fitting as a handy template;

I then repurposed a hose attachment from an old vacuum cleaner that I was throwing out and trimmed it down to make it flush on the underside;

I cut a corresponding hole in the steel to accomodate the hose attachment and then tapped some M3 threads for the bolts;

The end result was just about right, with the airflow keeping up with the vacuum suction;

Happy with that! Now to get this thing illuminated...